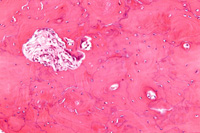

CAUSES: Cracking and flaking are advanced stages of checking. The breaks in the coating penetrate the film completely to the substrate. On surface which have received numerous coats of paint, the underlying layers lose their elasticity and are unable to expand and contract with the surface as it responds to temperature and humidity changes. As the wood swells, stress breaks the bond between layers to form checks.

CAUSES: Cracking and flaking are advanced stages of checking. The breaks in the coating penetrate the film completely to the substrate. On surface which have received numerous coats of paint, the underlying layers lose their elasticity and are unable to expand and contract with the surface as it responds to temperature and humidity changes. As the wood swells, stress breaks the bond between layers to form checks.

Additional swelling widens the breaks to form cracks. Because wood expands to a greater extent between grain lines, more force is exerted across the grain. Cracks are, therefore, more likely to form with the grain. If the surface is plywood or flat-grain wood, the material itself is likely to crack eventually, which causes the paint film to crack also. Finish coats for plywood should, at minimum, be 100% acrylic latex, but elastomeric are the best of all for plywood.

If cracking at plywood joints is severe, caulk the joints with a good grade of acrylic latex or elastomeric-type caulk. This prevents further moisture from penetrating the laminations of the plywood. Failure to adequately prime and protect pressed composition boards and siding can also result in cracking.

SOLUTIONS: Cracking down to the wood usually requires the complete removal of the coating, repriming and repainting. In cases where cracking occurs over plywood, only periodic scraping, sanding, repriming and recoating will solve the problem. Latex paints will usually fill plywood cracks better than oil-based materials. Try a latex exterior primer and a good grade of latex finish coat. Pressed composition boards should be primed immediately following installation, and adequate coating should be kept on the surface at times to seal out moisture.